Stainless Steel Wall Cladding FAQ's

Stainless Steel Wall Cladding – Durable, Hygienic Steel Cladding Sheets for Demanding Environments

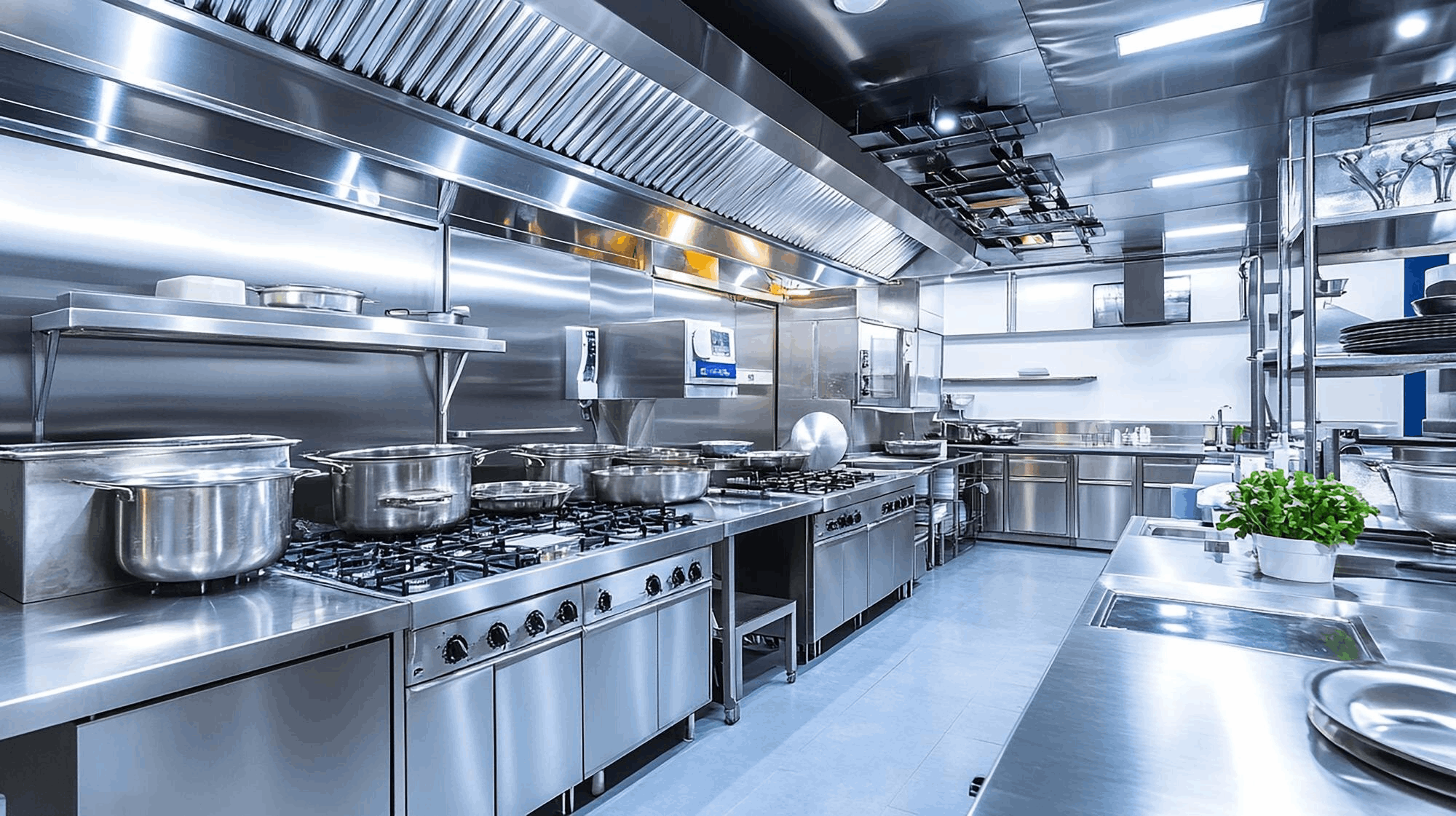

Stainless steel wall cladding is designed for environments that require a hard-wearing, hygienic, and fire-resistant surface. It’s commonly used in commercial kitchens, food processing plants, laboratories, cleanrooms, and industrial settings. The smooth, non-porous surface is easy to clean, highly durable, and resistant to corrosion, making it ideal where hygiene and long-term performance are essential.

Our stainless steel wall cladding is available in two standard sizes: 2.4m x 1.0m x 0.9mm and 2.4m x 1.2m x 0.9mm. These sizes are suitable for a wide range of applications and can be trimmed or shaped on-site if needed. The 0.9mm thickness provides strength and impact resistance, ensuring long-lasting protection for your walls.

Stainless steel cladding offers exceptional durability, heat resistance, and hygiene compared to many other materials. Unlike tiles or painted surfaces, it doesn’t crack, peel, or absorb moisture. It’s ideal for areas exposed to high temperatures, heavy use, or stringent cleanliness requirements. Stainless cladding also provides a sleek, professional appearance that suits both industrial and modern commercial interiors.

Yes. Stainless steel wall cladding can be installed using adhesives or mechanical fixings depending on the substrate and environment. Once in place, it's very low maintenance—simply wipe it down with mild detergent and water to keep it clean. Its resistance to staining, rust, and chemical damage makes it a practical choice for both heavy-duty and hygienic settings.